As an Amazon Associate I earn from qualifying purchases.

Welcome to the ultimate guide to “What Is the Liquid Line on an Air Conditioner?” Suppose you’ve wondered how air conditioners work their magic in providing comfort during scorching summers. In that case, you’ve come to the right place. In this comprehensive article, we’ll take a deep dive into the inner workings of air conditioners, focusing on the critical component known as the liquid line.

Air conditioning systems are intricate and fascinating, and understanding their various parts can empower you to make informed decisions about maintenance and troubleshooting. The liquid line plays a pivotal role in the refrigeration cycle, ensuring that the refrigerant flows efficiently to deliver cooling relief to your living spaces.

What is the Liquid Line on an Air Conditioner?

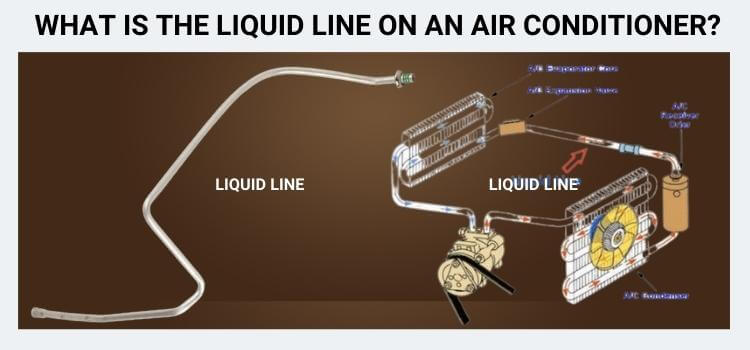

The liquid line on an air conditioner is a pipe that carries the liquid refrigerant from the condenser coil to the expansion valve. The fluid line is typically made of copper tubing and is insulated to prevent heat loss. The liquid refrigerant in the line is very cold and under high pressure. This is why the fluid line often feels cold to the touch.

The liquid line is essential to the air conditioning system because it helps transfer heat from the condenser coil to the expansion valve. The heated refrigerant gas is cooled by the condenser coil, which is situated outside the air conditioner.

The expansion valve then reduces the pressure of the refrigerant gas, which causes it to vaporize and absorb heat from the surrounding air.

If the liquid line is damaged or restricted, the air conditioning system’s performance can be affected. A damaged or delayed fluid line can cause the air conditioner not to cool properly or run inefficiently.

Here are some of the causes of a cold liquid line on an air conditioner:

- Undercharge of refrigerant: If the air conditioner is not properly charged with refrigerant, the liquid line will feel cold to the touch.

- Restriction in the liquid line: A rule in the liquid line can cause the refrigerant to flow more slowly, making the fluid line feel cold.

- Faulty expansion valve: A faulty expansion valve can cause the refrigerant to vaporize too quickly, making the liquid line feel cold.

Suppose you notice that the liquid line on your air conditioner is cold. If this is the case, it is crucial to have a certified technician inspect the air conditioner to determine the root of the issue.

Understanding the Refrigeration Cycle

It is imperative to have a fundamental understanding of the refrigeration cycle. This mechanism allows cooling in an air conditioning system, in total recognition of the liquid line. The cycle involves four main components: the compressor, condenser, expansion valve, and evaporator. These parts cooperate to move refrigerant, which absorbs heat from the interior air and dissipates it outside.

- Compressor: The compressor is the heart of the refrigeration cycle. It pressurizes the refrigerant, raising its temperature and converting it into a high-pressure, high-temperature gas.

- Condenser: The hot, high-pressure gas refrigerant flows to the condenser, releasing heat to the outside environment. As a result, the refrigerant condenses into a high-pressure, high-temperature liquid.

- Expansion Valve: After leaving the condenser, the high-pressure liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature.

- Evaporator: The now low-pressure, low-temperature liquid refrigerant enters the evaporator coil. Heat is absorbed as indoor air blows over the evaporator coil, causing the refrigerant to evaporate and transform into a low-pressure gas again.

The Role of the Liquid Line

Now that we understand the basics of the refrigeration cycle let’s focus on the specific role of the liquid line in this process. The fluid line acts as a bridge between the condenser and the evaporator, facilitating the movement of the high-pressure liquid refrigerant.

- Carrying Liquid Refrigerant: The primary function of the liquid line is to transport the high-pressure liquid refrigerant from the condenser to the evaporator. In its liquid state, this refrigerant contains high heat energy. It will be released in the evaporator coil to cool the indoor air.

- Pressure Regulation: The fluid line also helps regulate the pressure of the refrigerant as it moves from the high-pressure condenser to the low-pressure evaporator. This pressure drop is crucial for the refrigerant to change from liquid to gas in the evaporator, absorbing heat.

- Refrigerant Flow Control: Proper sizing and insulation of the liquid line are crucial for controlling the flow rate of the refrigerant. An optimally sized and insulated fluid line ensures the suitable refrigerant reaches the evaporator, maximizing cooling efficiency.

Importance of a Well-Functioning Liquid Line

A well-functioning liquid line is vital for an air conditioning system’s efficiency and effectiveness. Here are some reasons why the fluid line’s proper functioning is essential:

- Optimal Cooling Performance: A well-designed and adequately insulated liquid cable ensures the right amount of liquid refrigerant reaches the evaporator coil. This, in turn, guarantees efficient heat absorption, resulting in optimal cooling performance.

- Energy Efficiency: The air conditioner works more effectively and uses less energy to provide the needed cooling when the fluid line is appropriately sized and insulated. This not only reduces energy bills but also contributes to environmental sustainability.

- Avoiding Refrigerant Issues: A malfunctioning liquid line can lead to refrigerant-related problems, such as liquid slugging and improper refrigerant flow. These issues can cause damage to the compressor and other components, leading to costly repairs.

- Extended System Lifespan: By ensuring the smooth flow of refrigerant, the liquid line helps reduce strain on the air conditioner’s components. This can extend the system’s lifespan and minimize the need for frequent repairs.

- Improved Comfort: A properly functioning liquid line ensures consistent and even cooling throughout the indoor space, providing occupants with a comfortable and enjoyable environment.

The Role of Refrigerant in the Liquid Line

The refrigerant in the liquid line plays a pivotal role in the cooling process. The most common type of refrigerant used in modern air conditioning systems is R-410A, known for its environmental friendliness and efficiency. When the high-pressure, high-temperature refrigerant enters the liquid line from the condenser, it changes, becoming a high-pressure liquid.

The refrigerant then flows through the liquid line, passing through a filter-drier that removes moisture and contaminants. This ensures the refrigerant remains clean and optimizes system performance. The refrigerant in liquid form is passed through the expansion valve. Once it enters the valve, its pressure drops considerably, leading to its evaporation in the evaporator coil.

A cycle of comfort is created when the refrigerant evaporates by absorbing heat from the interior air and cooling it. The gaseous refrigerant is then drawn back to the compressor, where the process starts anew.

Common Issues with the Liquid Line

While the liquid line is a crucial component, it is not immune to problems. Some common issues that can arise with the fluid line include:

- Refrigerant Leaks: The liquid line can develop small leaks over time, decreasing refrigerant levels. Low refrigerant levels can negatively impact the cooling performance of the air conditioner.

- Clogging: Dirt, debris, or other contaminants can accumulate in the liquid line, causing clogs. These obstructions can disrupt the flow of refrigerant, leading to inefficient cooling.

- Improper Insulation: Inadequate insulation on the liquid line can cause the refrigerant to absorb heat from the surrounding environment. This can result in higher refrigerant temperatures and reduced cooling efficiency.

- Corrosion: The liquid line is exposed to the outdoor elements, making it susceptible to decay over time. Corrosion can weaken the line and potentially lead to refrigerant leaks.

FAQs

Yes, you can visually inspect the liquid line for any visible signs of damage, such as leaks or corrosion. However, leaving more in-depth inspections and repairs to trained HVAC professionals for safety and accuracy is recommended.

The liquid line and other air conditioning components should be checked during regular maintenance visits, typically conducted annually. Regular maintenance helps identify and address any issues before they become significant problems.

A clogged liquid line can disrupt the refrigerant flow, reducing the air conditioner’s cooling capacity. This may lead to ineffective cooling, increased energy use, and decreased interior comfort.

No, ice formation on the liquid line is abnormal and may indicate a refrigerant leak or other issues. If you notice ice on the fluid line, it’s essential to have it inspected by a qualified HVAC technician.

Sometimes, a professional HVAC technician can repair minor leaks in the liquid line. However, extensive damage or corrosion may require replacing the entire line.

Scheduling professional maintenance with an HVAC expert will ensure all air conditioning system components work optimally.

Conclusion

Understanding the liquid line’s role and importance in an air conditioning system is essential for ensuring efficient cooling and prolonging the system’s lifespan. The fluid line acts as a conduit for the high-pressure liquid refrigerant. It facilitates its journey from the condenser to the evaporator coil, where cooling magic happens. Homeowners can enjoy optimal comfort and energy-efficient cooling throughout the hot summer months by promptly maintaining the liquid line and addressing any issues.

Related Post

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.

Leave a Reply